1、Mechanical Seals Installation:

1.Check the installed mechanical seals types,sizes right or not.

2.Check the machine relatad sizes tolerance, form, position tolerance and surface roughness whether meet the technic requirements.The main requirements are as follows:

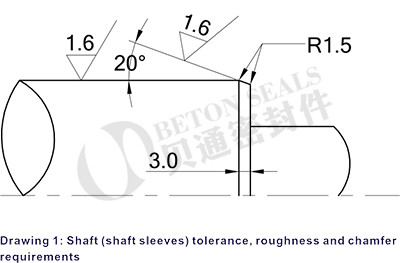

(1)The installed mechanical seals shaft (orshaft sleeve ) radial direction jumpiness within 0.06mm.Shaft (shaft sleeve)surface roughness and extemal diameter tolerance.

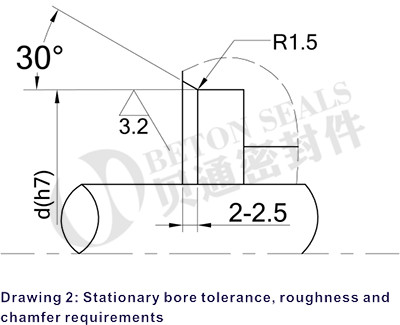

(2)The end of shaft (or shaft sleeve )be installed mechanical seals rotary, the end of bore for installing mechanical seals stationary seat,chamfer, roughness, tolerance should accord with drawing 1 and drawing 2.

(3)The shaft(or shaft sleeve)with mechanical seals during working the axial movement should within 0.3mm.

3.During mechanical seals installing should keep cleanliness,prohibit knocking the seals parts,otherwise will result in seal rings be deformed or the ceramic rings destroyed.

4.To ensure right installation secondary seal rings (rotary and stationary seal rings)should be daubed sllicon grease lubricant before install.The EPDM can not contact mineral oil.

5.Use degreased gauze to clean the rotary and stationary rings surfaces, put3 to 4 drops cleaned oil on the seal faces.

6.The Rotary parts will be fixed by spring seat set screws and shaft. Should notice the mechanical seals working height when tightening the set screws.

7.To keep the uprightness between axes line and stationary ring when installing the gland should equably tighten the set screws.

8.After installed please to check the shaft whethereasy running. lf hard to rotate should check the related sizes.

2、Mechanical Seals Usage:

1.for the crystal, granule medium, medium temperature>80C.Please take the relevant steps to flush,sieve,cool, the others assistant devices please follow the related standards of mechanical seals.

2.Please check the mechanical seals assistant devices before the machine operate,cooling lubricative system whether on working.

3.The mechanical seals cavity should full of medium before the machine operate. lf with separate sealing system which should 5 to 10 minutes earlier operate.the cooling system is the same with separate sealing system.

4.lf you want to operate the machine please take the first step for natural pressure running and observe the sealed place temperature and leakage volume.If have fewer leakage, let it continue running until reach to normal leakage.After 1 to 3 hours running, if the leakage still can not reach to normal leakage, in this case have to stop the machine running.

5.When stop working, first stop the machine running then for the lubrictive system!

No data at this point